Vehicle lifting platform

Your individual vehicle lifting platform

We offer both overfloor systems (lifting jacks) as well as underfloor systems. Both systems make it possible to lift not only individual vehicles, but also complete vehicle sets without having to decouple them.

Product

Overfloor systems are fixed or equipped with a chassis. The mobile lifting gears are available in all variants: as rail suspension or landing gear, with or without traction drive. For the reception of the rail vehicles, the hoofs can be equipped with fixed or adjustable outings and the corresponding load pads.

Underfloor lifting systems can be designed for lifting individual components, such as individual bogets, or entire vehicles. With our systems, you can realize extremely efficient lifting lines, where by combining bogie and car box jacks, several bogies can be changed at the same time without having to lower the vehicle in between.

If you need systems for maintenance, but want to do without foundation work, then our overfloor systems are exactly right. They provide optimal maintenance access to the underside of the rail vehicles.

We produce the control of the plants ourselves. Our safety PLC with integrated synchronisation control fully complies with the final DIN EN 1493 for vehicle lifting platforms.

Applications

The BÜTER vehicle lifting systems are mainly used in the rail vehicle industry, but also for lifting trucks, buses, construction machinery, tanks, etc. They are mainly used for the maintenance and maintenance of the vehicles.

Properties

- Both overfloor and underfloor systems

- Flexible to suit your needs thanks to numerous designs

- Easy-to-understand and safe operation

- Safe lifting system with self-locking trapezoidal thread spindle

- Foundationless in mobile systems, usable on several tracks

- Expandable by additional equipment such as mobile support blocks, load beams, etc.

- Individually programmable system control according to your requirements

- Safety PLC with integrated synchronisation control according to DIN EN 1493

- Robust, durable, low-maintenance machines

Your benefits and benefits

- Long service life: Durable construction, designed exclusively with high-quality components.

- High security: Our systems are designed for maximum work and operational safety and meet the latest safety standards.

- Efficient workflows: Design your workflows with maximum efficiency by realizing lifting lines tailored to your needs

- Smooth operation: We manufacture and store almost all spare parts ourselves. Therefore, we deliver every spare part within the shortest possible time.

- Low investment costs: On request, we supply systems that require no or only a few foundation work (working pits).

- Expandable plants: Our systems can be flexibly expanded and adapted to changing requirements.

Benefit from our many years of experience

in the area of vehicle lifting platforms

Individually according to your wishes

We produce your vehicle lifting platforms exactly according to your wishes and specifications. Whether standard products or special solutions, we have the right and tailor-made solution for all industrial sectors.

Production & service from a single source

We manufacture almost every single part of our vehicle lifting platforms directly on site. This gives you above-average quality and our fast service for maintenance and repairs.

Spare parts

Since we manufacture each assembly of vehicle lifting platforms on site, we have many standard components in stock and can provide them to you quickly. We can produce special components at short notice.

Sustainable

With our site production, we reduce transport, emissions and traffic. We manufacture our vehicle lifting platforms sustainably through optimized production processes and production processes.

Fast offer creation

We create a tailor-made offer for you at lightning speed. Thanks to our many years of experience and our wealth of knowledge, we will quickly find the optimal vehicle lifting platforms solution for you.

24-Month warranty

Examples of our vehicle lifting platforms

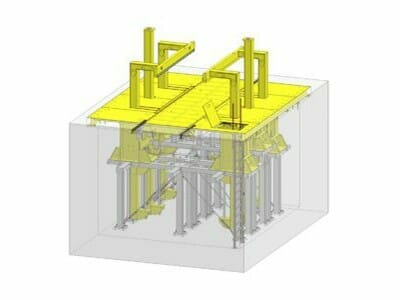

Vehicle lifting system 8 x 16 t

Hebebock 16 to

Spindle drive on top and spindle protection via bellows

Floor landing gear and power supply from above

Lifting drive

Column guidance

Lifting system with bogie and car box lifter

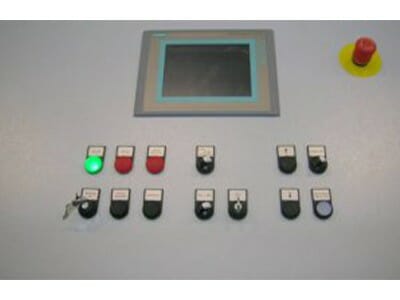

Master control cabinet with safety PLC

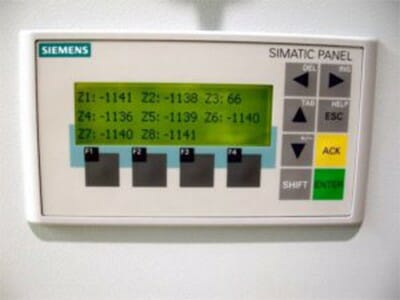

Operator panel with display of lifting heights

Central control via TouchPanel

Adjustable load pads for different vehicle types

Lifting portal with adjustable cross-traverse

Vehicle lifting platforms for your company

Were we able to arouse your interest in a vehicle lifting platforms?