Manufacturer of component lifting systems

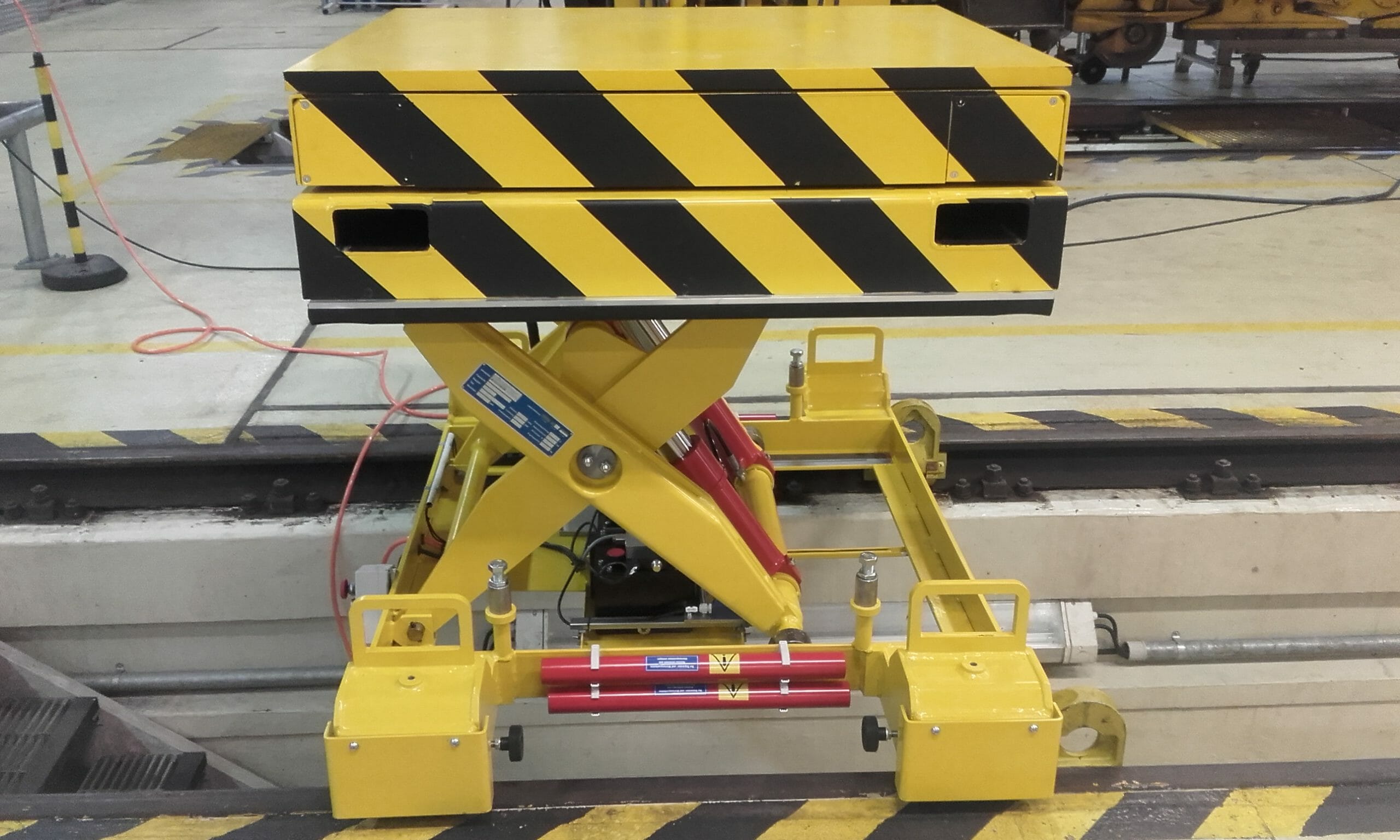

BÜTER component lifting systems: Perfectly configured for efficient operation

Thanks to our long experience in railway technology, we know the needs and workflows in detail. This is reflected in our wide range of component lifting systems. You can choose between stationary or mobile versions, in the mobile versions between corridor-accessible models and 2-way vehicles with battery drive and driving drawbar operation.

The lifting platform can be equipped with a wide variety of images so that you can charge any desired component (e.g. battery systems or air conditioners). Sliding and/or tilting platforms are also available for compensating for ground unevenness.

Applications

The component lifting systems are used for maintenance and maintenance work on the rail vehicle, in particular for lateral transfer/transfer of components such as batteries or air conditioning units.

Properties

- Flexible adaptation to the respective application, thus versatile

- Mobile systems, usable in many places along the track

- Battery-electric drive and hoist drive

- Easy and safe handling

- Compact design with innovatively designed lifting platform

- Sliding solid rollers; Low-maintenance plain bearings

- Hydraulic cylinders from our own production

Your benefits and benefits

- Cheap investment thanks to versatile and flexibly customizable systems.

- Quickly and safely movable and usable.

- Long service life: Durable construction, designed exclusively with high-quality components.

- Low maintenance costs thanks to low-maintenance components.

- Efficient use of space: Space-saving construction with high power density.

- High operational readiness thanks to rapid delivery of spare parts

Benefit from our many years of experience

in the area of component lifting systems

Individually according to your wishes

We produce your component lifting systems exactly according to your wishes and specifications. Whether standard products or special solutions, we have the right and tailor-made solution for all industrial sectors.

Production & service from a single source

We manufacture almost every single part of our component lifting systems directly on site. This gives you above-average quality and our fast service for maintenance and repairs.

Spare parts

Since we manufacture each assembly of component lifting systems on site, we have many standard components in stock and can provide them to you quickly. We can produce special components at short notice.

Sustainable

With our site production, we reduce transport, emissions and traffic. We manufacture our component lifting systems sustainably through optimized production processes and production processes.

Fast offer creation

We create a tailor-made offer for you at lightning speed. Thanks to our many years of experience and our wealth of knowledge, we will quickly find the optimal component lifting systems solution for you.

24-Month warranty

Examples of our component lifting systems

Length: 1000 mm

Width: 1450 mm

Payload: 1200 Kg

Useful stroke: 500 mm

Length: 1000 mm

Width: 1450 mm

Payload: 1200 Kg

Useful stroke: 500 mm

Length: 1200 mm

Width: 1200 mm

Payload: 4000 Kg

Useful stroke: 400 mm

Component lifting system for your company

Were we able to arouse your interest in a component lifting system?